Biomass Pellet Machine Line

Customized according to client’s needs

We provide customized line for pellet making. Our engineer team will design the line depend on client’s raw materials and request of the finished pellets.

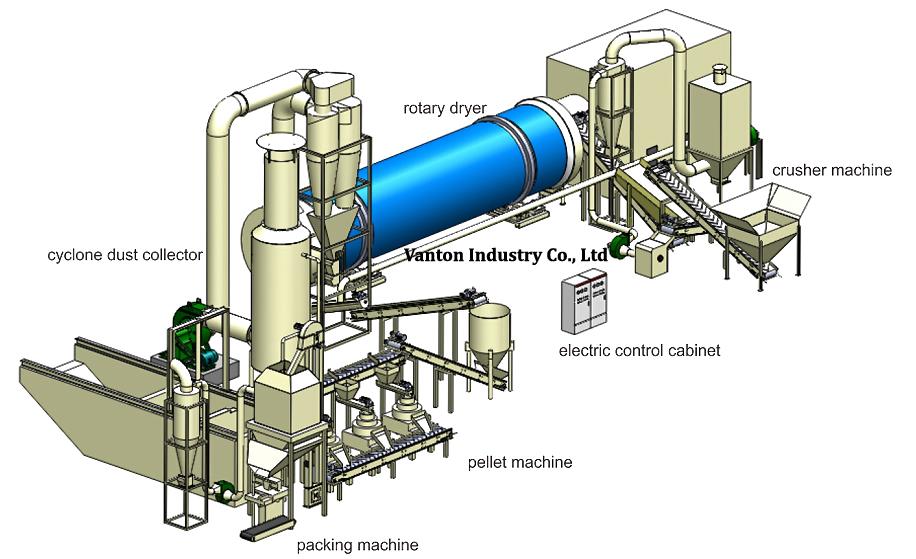

A complete line, that can make raw materials to pellets.

According to client’s need, we can provide Peeling Machine, Chipping Machine, Crushing Machine, Dryer, Pellet Mill, Pellet Cooler, Screen, Packing Machine, different types of Conveyor, Screw Feeder and so on.

- Peeling machine (debarker) – remove the tree bark. This kind of equipment is use for high quality pellets. Without tree bark, the pellets can be very clean, and have a bright color.

- Chipping Machine (wood chipper) – make big size of raw materials into small pieces (for example 3-5 cm). If the raw material is not big, this process is not necessary.

- Crushing Machine (hammer mill) – make pieces to powder (sawdust). The output size depends on the need of client. In some project the powder should be as fine as 0.5-1 mm.

- Dryer – drying process is also very important as the raw material may has high water moisture (35% or even as high as 60%). Using dryer, we reduce the water consent to about 15%. We have two kind of dryers, Air Flow Dryer and Drum Rotary Dryer. Customer can chose what he want, or by our suggestion.

- Pellet Machine – the most important equipment in the whole line, which can press powder to pellets. A good pellet mill should be stable, reliable, easy to use and has a long service life. For industry and commercial use we suggest to choose ring die pellet mill.

- Pellet Cooler – our cooler is designed with a screen. Which can reduce the temperature and select pellets at the same machine. After cooling, the pellets moisture can be reduced again – to 12%.

- Packing Machine – customer can choose the packing machine, to make small bags or big bags. Our packing machine is fully automatic, very easy to use.

- Other equipments – palletizer, conveyor, screw, hopper, frame, filter… is also important to the production line. According to the budget of client, we will suggest thees equipments.