Wood Pellet Production Line

Capacity: 2-2.5t/h

We provide customized line for pellet making. Our engineer team will design the line depend on client’s raw materials and request of the finished pellets.

Biomass Pellets Raw Materials:

Wood chips, logs, sawdust, waste wood, bark, straw, wheat straw, rice husk, cotton stalk, coconut slag, sunflower stalk, olive slag, grass, bamboo, paper, cassava, peanut shell, corn cob, Soybean straw, weeds, wood branches, leaves, etc.

The finished pellet diameter is usually 6 mm and 8 mm. It can be adjusted according to client’s need.

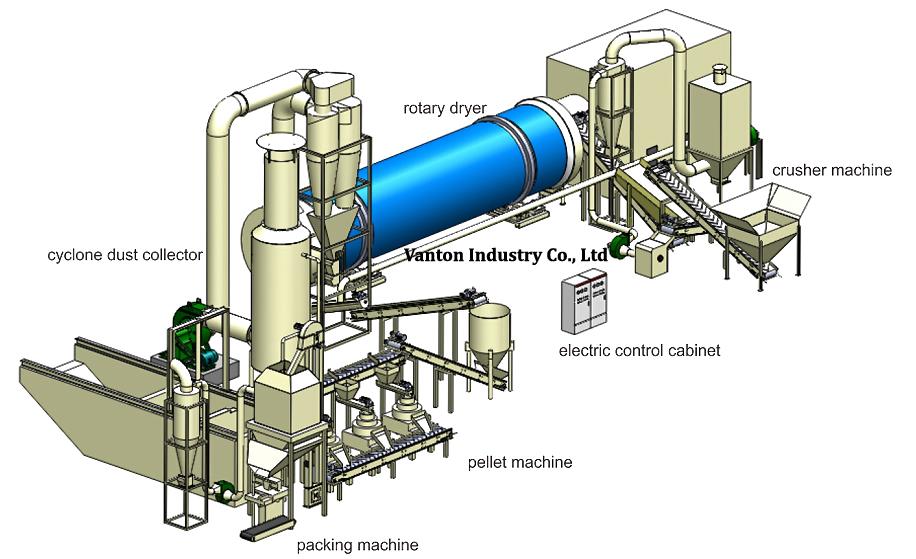

Wood Pellet Production Line

It mainly contains of Chipping process, Crushing process, Drying process, Pelletizing process, Cooling and Screening process and Packing process.

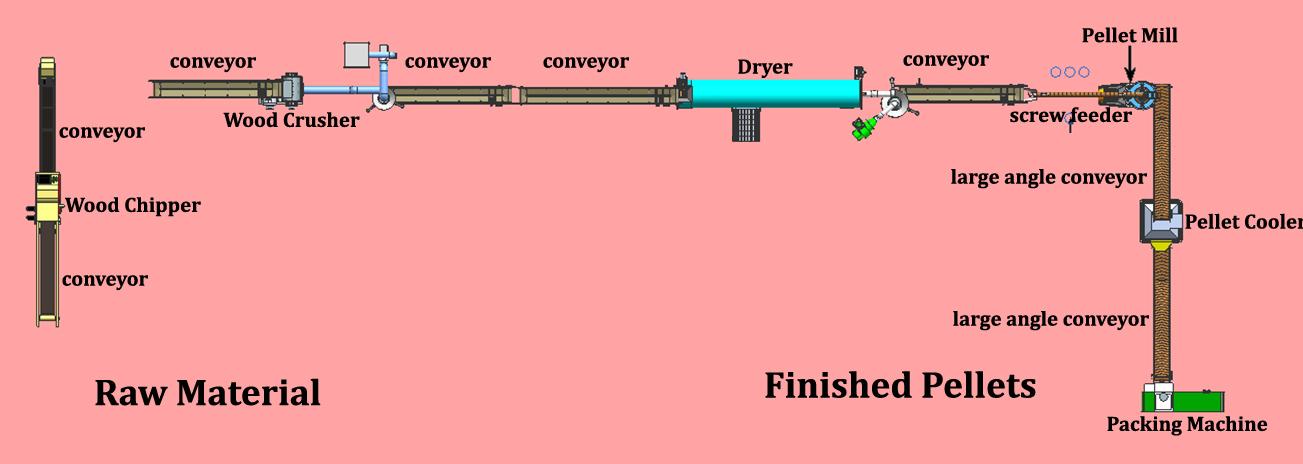

1. Chipping process- Wood chipper

If the raw material’s size are big, the first step is to make them small. Crushing machine’s input demind is 3-5 cm (the most suitable size), if the raw material is biger, or long shape, need to make them to chips, and then to powder.

2. Crushing process – Hammer mill

Hammer mill crushes chips into sawdust (or other kind of powder). Usually the discharge size is about 3mm. If client has request, can change the screen to get other discharge size.

3. Drying process – Drum rotary dryer

Before pelletizing, neet to control the water mositure for the raw material. Client should add water, or dry them to get 15% water content.

4. Pelletzing process – Pellet mill

The pellet mill, also named as pellet press. It can press the prepared material into pellets. Ring Die Pellet Mill is a very classic type of pellet mill, which has good performance and effictive.

5. Cooling process – Pellet cooling machine

After the pelleting process, the temperature of the wood pellet is about 60-80 degrees Celsius, and the moisture content of the wood pellets is about 15%. A cooler should be used to reduce the moisture content to about 3% and the temprecher to room emperature.

6. Packing process – Pellet packing machine

To avoid the pellets from damp, and for further sale, the pellets should be packaged.

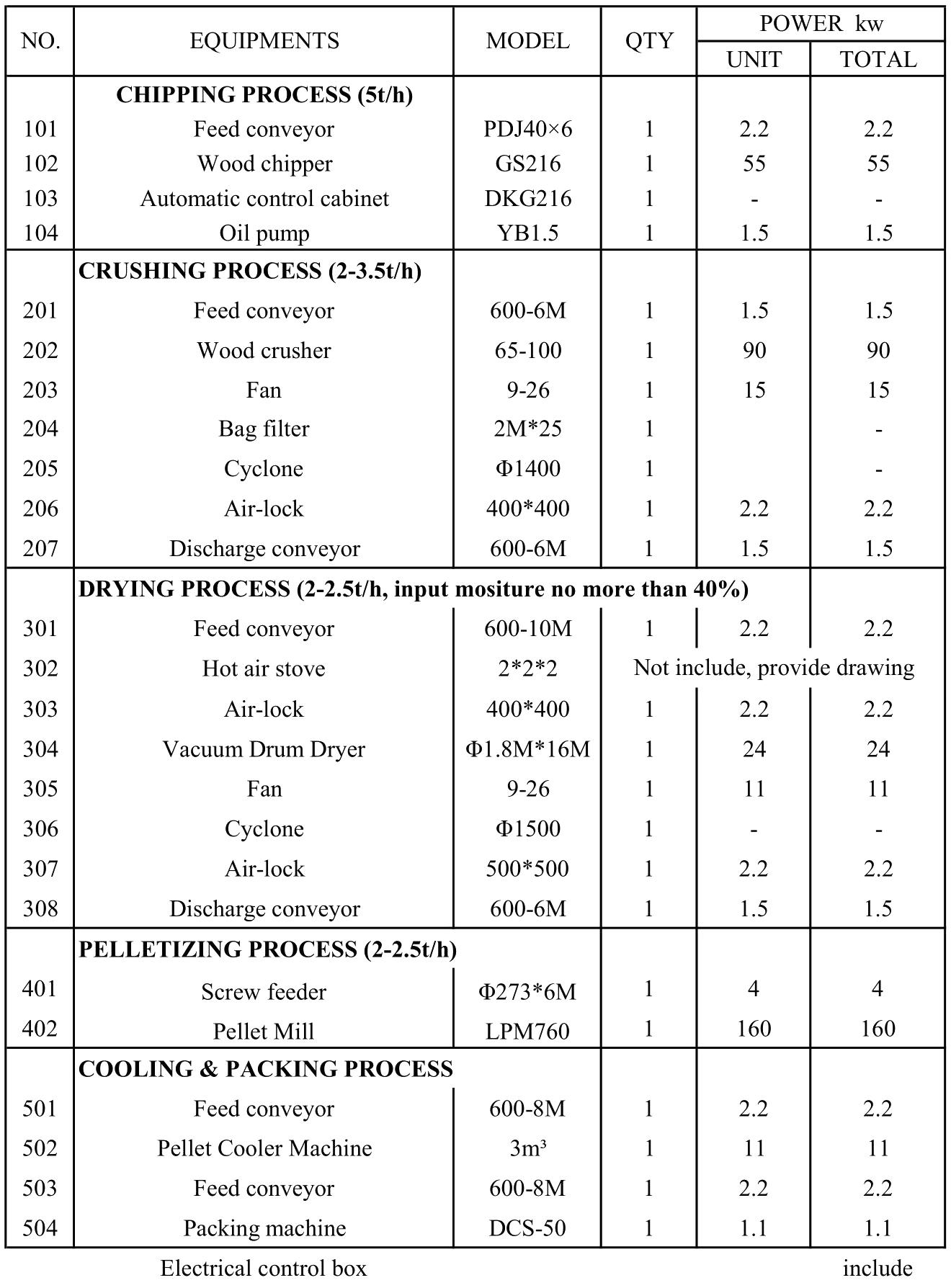

Equipments for 2-2.5t/h Producing Line

(The below equipmets are for example. The detailed plant should according to the client’s needs)

Related equipments

- Chipping Process —— Drum wood chipper GWC216

- Crushing Process —— Wood crusher LHM65x100

- Drying Process —— Vacuum drum dryer VD1.8*8

- Pelletizing Process —— Pellet machine LPM760

- Cooling Process —— Pellet cooler NLC3, Packing machine DCS-50