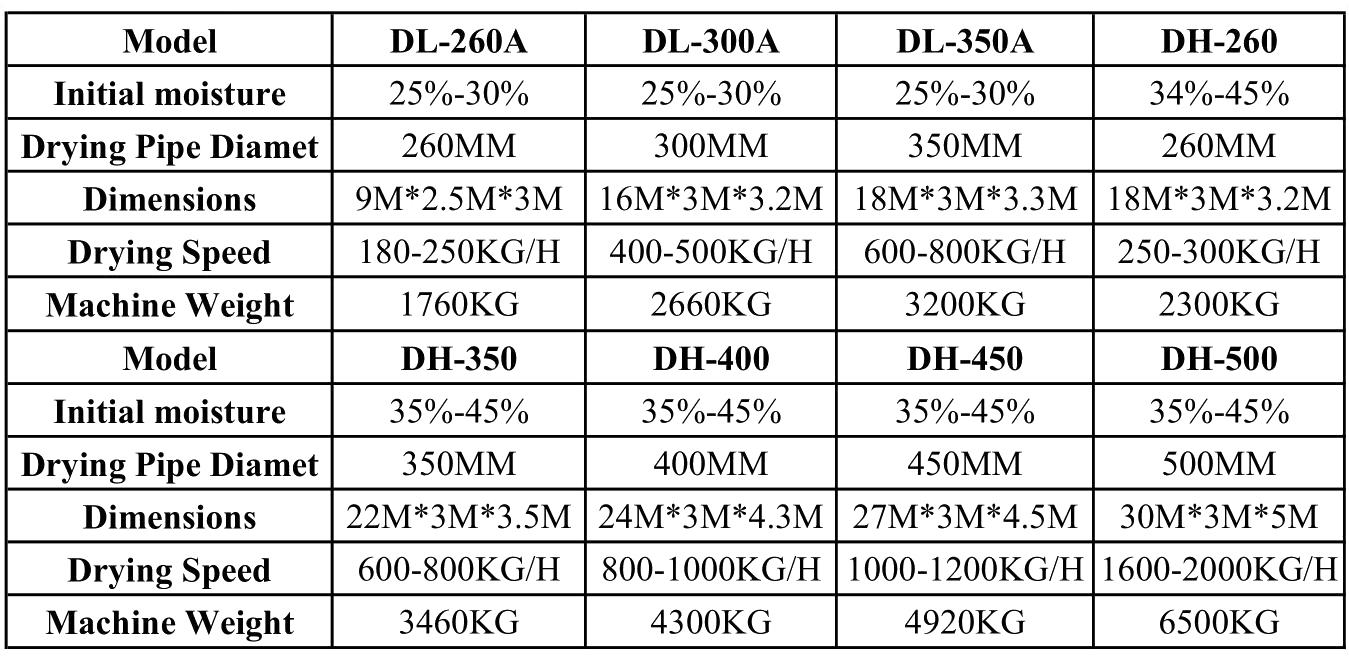

Air-flow Dryer DL300B

25-30% moisture, 0.4-0.5t/h

The air flow dryer is using hot air from a hot blast stove to dry materials. This machine is suitable for different materials, such as wood chips, different kinds of grains and straws and other materials.

Introduction of Air-flow Dryer:

Before making pellets, drying is important. In order to obtain high-quality and high-quality biomass masses, the moisture content of the material must be precisely controlled at 8-12%. The choice of drying equipment model depends on the original moisture content of the raw materials.

Wood dryers are suitable for drying materials such as sawdust, wood shavings, rice husks, wheat straw mills and corn straws.

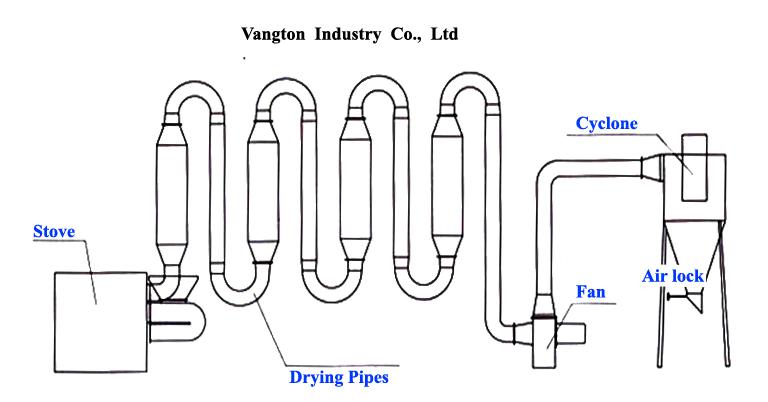

Working Principle of air-flow dryer:

The whole system consists of blower, engine, fuel oil boiler, steel pipe, cyclone separator and air lock. In this system, wet material is fed into the hopper through a screw feeder. Fuel stoves produce a lot of hot air. The hot air is sent to the steel pipe, mixed with the wet wood chips, and passed through the curved pipe and the drying chamber by the force of a blower. The fast-moving hot air is maintained and mixed with the raw materials conveyed through the steel pipe in a floating state by the screw feeder.

Structure of Air-flow Dryer

Hot air flow dryer for sawdust

Hot air flow dryer for sawdust