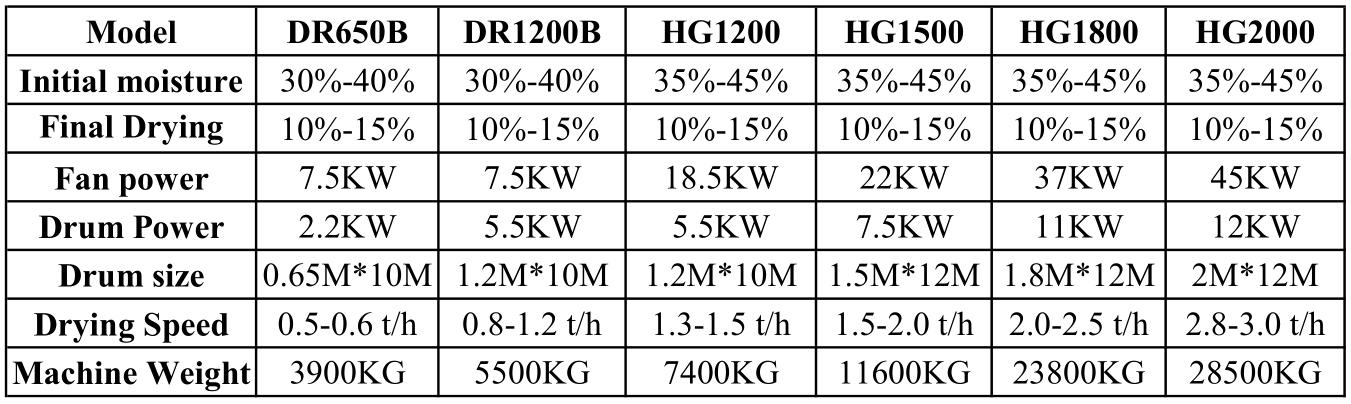

Drum Rotary Dryer HG2000

35-45% moisture, 2.8-3t/h

Drum rotary dryers are used for drying water from raw materials using a drying drum. In the drum during the drying process, raw materials are dried by a rotating drum, thereby producing a drum-dried product. Drum dryers are suitable for industries such as fuel plants, fertilizer plants, chemical plants, and pharmaceuticals.

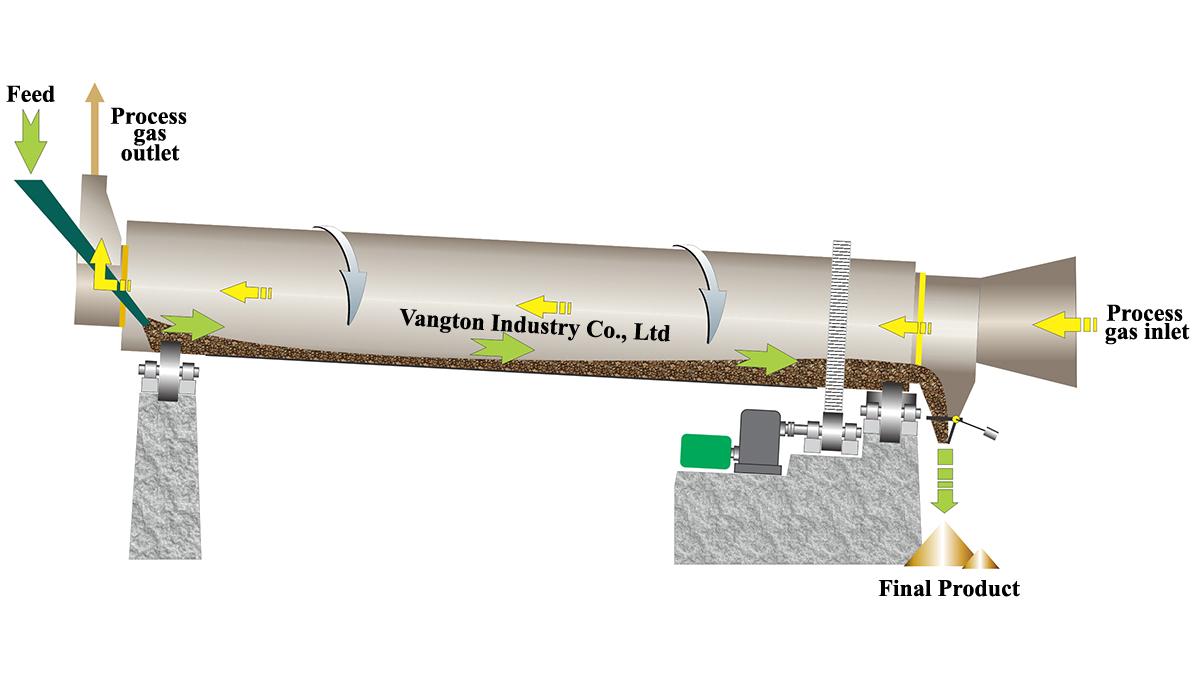

The working principle of the direct-heating rotary dryer is to lift and spray the product by hot air flowing in parallel or inverse direction, while the indirect dryer is more suitable for fine dust materials with little or no contact because the product and drying gas are heated from the outside , So they are heated externally through a fixed jacket with multiple burners or other external heat sources.

The efficiency of the dryer is largely determined by the difference between the inlet temperature and the exhaust gas temperature, although the heat transfer rate is also affected by the relationship between the blade design and the speed. However, regardless of the temperature of the gas and material, the drying (or dwelling) time is critical because it depends on the rate of water diffusion from the core to the material surface.

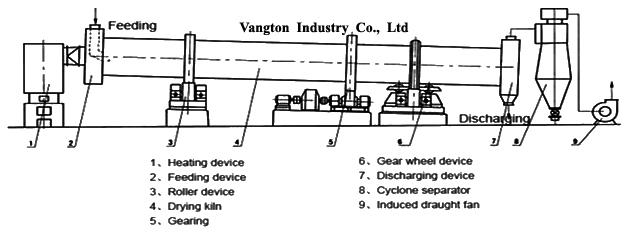

Wood dryer principle

The wet material is conveyed to the hopper through a belt conveyor or bucket elevator, and then enters the feeding end through the hopper feeder and the feeding pipe in turn. The inclination of the feeding tube must be greater than the natural inclination of the material to allow the material to flow smoothly into the dryer. The horizontal line of the dryer is slightly inclined.