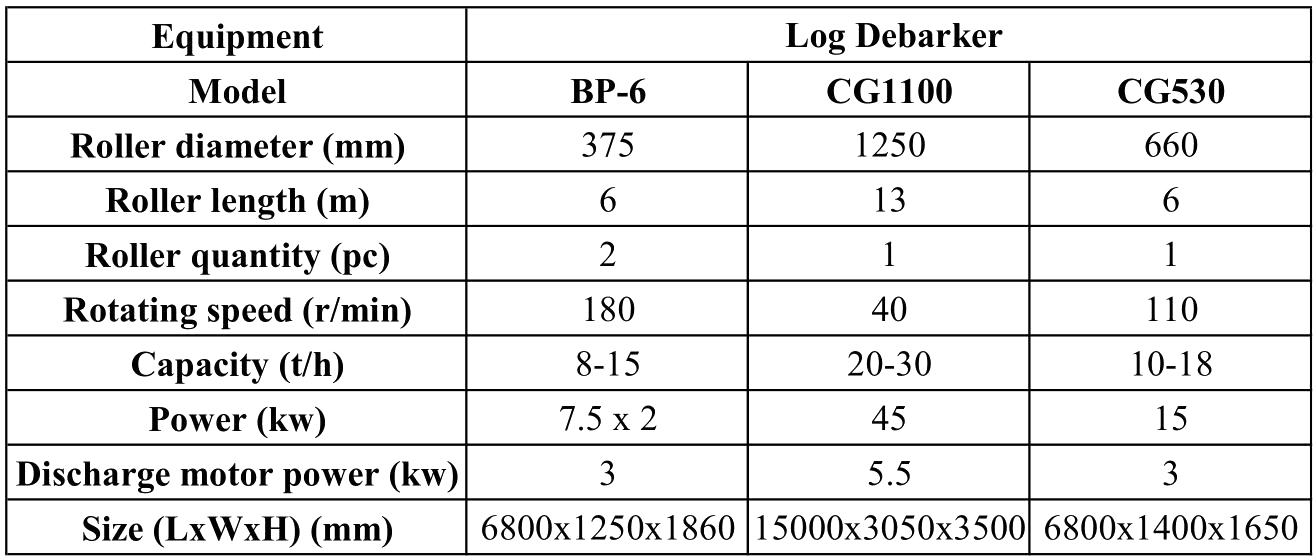

LOG DEBARKER BP-6

6m length log debarker machine

Log debarker machines are widely used in paper mills to produce uniform wood chips for the manufacture of pulp. The peeling rate is as high as 95%, the output chip is even and beautiful.

The log debarker (wood peeling machine) consists of five parts: the peeling roller, the feed opening, the bark discharge, the log discharge and the power drive. It has a separate bark outlet and a log drain for continuous operation, enabling continuous line work from feed to stripping to log discharge.

Wood log debarker features:

1. Use four-point tool, easy to use and low cost.

2. The voltage is controlled by hydraulic knife, with advanced structure and reliable performance.

3, the continuous change feeding mechanism of frozen materials, bent wood, eucalyptus, oak, eucalyptus and other trees, with a good hard skin peeling effect.

4, high cleanliness, high productivity, small damage to wood

The working principle of the log debarker:

1. The peeler uses an open hopper that can be supplied from one head to the other while the other has no material. It overcomes the shortcomings of existing roll strippers.

2. Due to the impact of the impact of the teeth on the wood part of the wood peeling machine, not only the wood part circulates in the outer shell, but also rotates around itself, so the peeling machine is highly efficient, and the eucalyptus and poplar trees have better peeling effect. , the clarity is greater than 95%

3, wood peeling machine is adaptable to wood. It can strip the length and shape of different tree species, the diameter and shape of the wood clearing machine. Due to the rotational movement of the wooden portion and the irregular runout, the concave portion of the curved wood portion can also be in good contact with the peeling teeth. Therefore, the peeling speed of the bent logs is much higher than other types of rollers.

4. Because the wood casing is large, the wood peeling machine is fixed, so the energy consumption is small, the failure rate is low, the maintenance workload is small, and the vibration and noise are much lower than the drum type peeling machine. The wood remover can be produced by a machine landing machine, which is convenient to use even if the base is not installed.