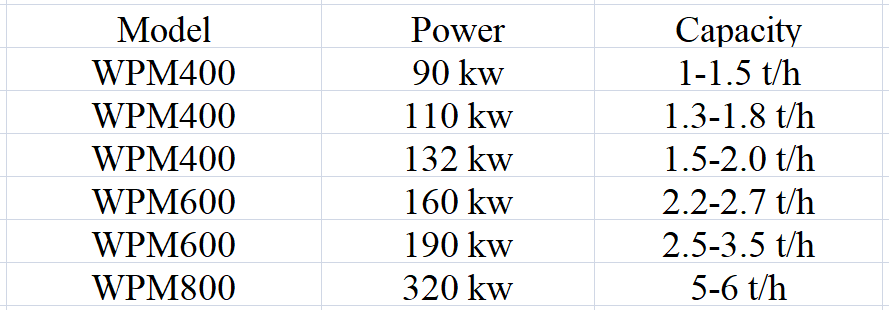

WOOD PELLET MACHINE WPM800

5-6t/h Biomass Pellet Mill

The WPM pellet machine is widely used for biomass pellets making. This series came earlier than LPM and NPM series, it is thought as a classic structure.

Vertical Pellet Machine Gear Box Pellet Machine Horizontal Pellet Machine Flat Die Pellet Machine

Introduction of wood pellet machine:

1). Wood pellet machine (granulator) is used to make agricultural and forestry waste into solid fuel or wood chips.

2). Wood pellet machines (granulators) include command feeder systems, stainless steel screw regulators, premium gearboxes, ring molds and lubrication systems.

3). The raw materials suitable for the wood pellet machine (granulator) are sent from the feeder to the granulation chamber. By rotating the rolls in the chamber, the material is forced through the holes of the mold to form pellets.

4). After the pellet machine (granulator) is granulated, the granulation length can be determined according to different requirements of the user.

Advantages of ring die pellet machine

The pellet machine can be seen as ring die pellet machine and flat die pellet machine by the structure. The ring die ones are more serious and bigger, they have below advantages.

A: The ring die pellet machine causes less wearing in production.

B: Ring die pellet machine is more powerful than flat die.

That’s why owners of industrial plants will choose ring die pellet machines. Ring die machines make it easier to produce high quality pellets and high efficiency products.

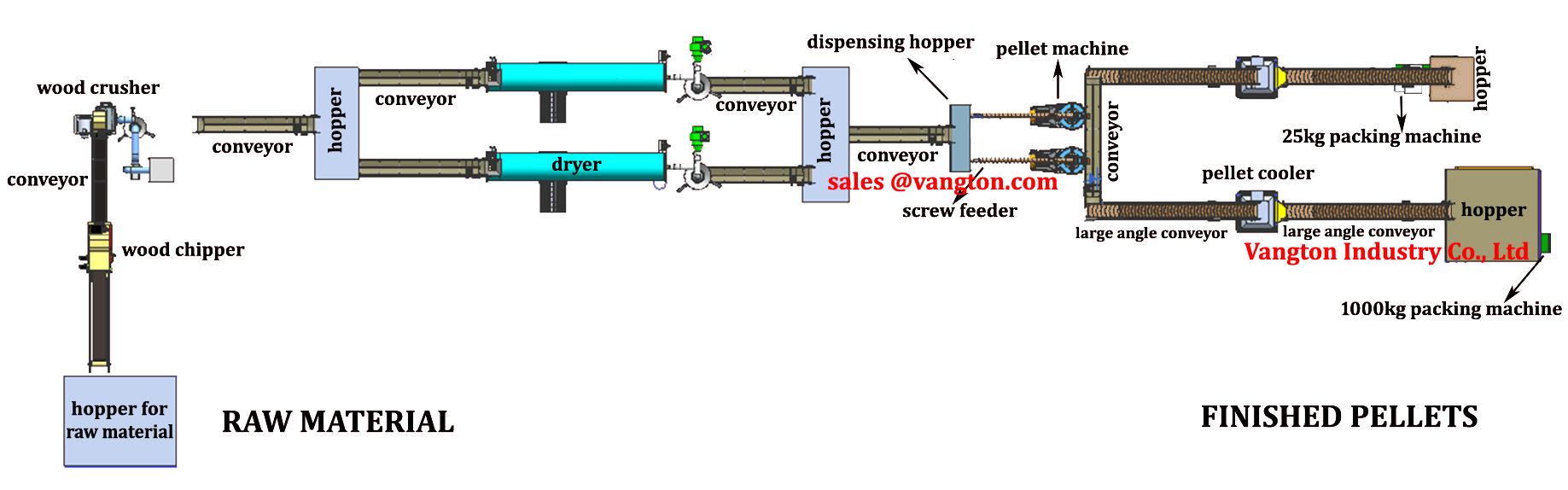

A complete biomass pellet machine line including: Wood Chipper, Wood Crusher (Hammer Mill), Dryer, Pellet Machine, Pellet Cooler, Packing Machine. If you need, we also have Debarker and Palletizer.

Different structures of pellet mills

Our Service

1) We can provide you with a one-year warranty, (not include spare parts).

2) Professional 24-hour after-sales service.

3) The relative recording of the machine’s installation and instructions will be provided to you.

4) We can provide you with different molds to meet your different requirements.

5) We can also meet special voltage requirements.

6) Engineers can repair machinery abroad